Equipment List

Pioneer Industries programs include: CATIA, PC-DMIS, Mastercam, SolidWorks and SIGMANEST

Accepted file formats include: CATPart, CATProduct, STP, IGES and DXF

Machining

CNC Horizontal Machining

- One Kitamura HX630G

- Four a61 Makino 4-axis Horizonal Mills

- One Automated Linear Pallet Pool (LLP)

CNC Lathe

- One 2600SY Doosan Y-Axis PUMA Turning Center

- One Bridgeport EZ-Path 14” x 20”

CNC Router

- Table size 60” x 144”

CNC Vertical Machining

- Five 3-axis <64” <20” <15″

- Five 4-axis <64” <20” <15”

Conventional Mills

- Five Conventional Mills

Sheet Metal & Forming

CNC Lasers

- One Bystronic fiber-optic laser 60" x 120" table, 6000W

- One Laser with 60” x 120” table, 4000W

- One Laser with 60" x 120" table, 3200W

CNC Punching

- High-speed close tolerance punching

- Brush table provides scratch-free processing

- Table size 48” x 120”

Complex Assembly Work

- Hardware installation

- Standoffs, sealants, studs and special fastener configurations

- Aerospace assembly of multiple components

Press Brakes

- Eight CNC press brakes, ranging from 4’ x 35 tons to 10’ x 80 tons

- Large inventory of precision tooling

Presses

- One Stretch Form Press

- One 100-Ton Punch Press

- One 150-Ton Punch Press

- One 400-Ton Punch Press

Water Jet Services

- Two large capacity CNC water jets 8’ x 12’

- One abrasive water jet 6’ x 12

Quality

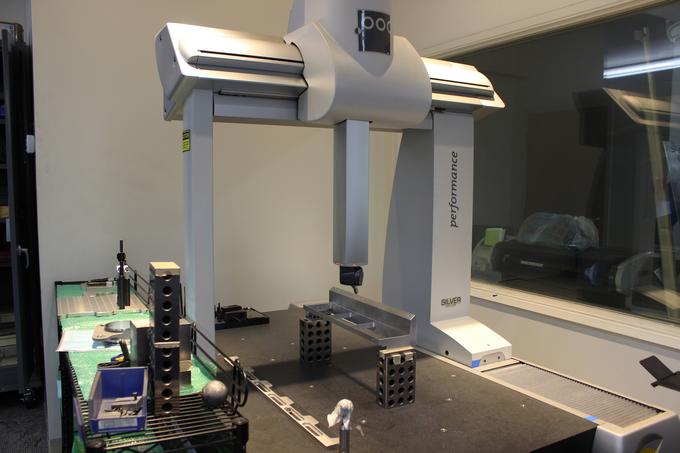

AS9100D Certified

- Global Silver Edition CMM (30x48x24)

- Global Silver Edition CMM (47x86x39)

- Starrett Vision System

- Fowler Trimos V4

Finishing

NADCAP Certified Chemical Treatment

- Boric acid – sulfuric acid anodize Class 1 and 5 – BAC 5632

- Chemical conversion of aluminum -MIL-C-5541 -MIL-DTL-5541 -BAC 5719

- Application of corrosion resistant finish for integral fuel tanks -BAC 5793

Onsite Finishing

- Conventional wet finishes

- Aircraft finishes

-

Pioneer Industries Environmental Statement:

Pioneer Industries, a manufacturer of aerospace products, is continually improving environmental processes and reducing environmental impact for customers and community through responsible business practices.