Aerospace Manufacturing

Pioneer Industries is the manufacturing arm of Pioneer Human Services. As a Tier 1 supplier with over 100,000 square feet of manufacturing space, we offer full-service CNC machining and sheet metal fabrication for the aerospace industry. We strive to provide exceptional value, turnkey solutions, and full integration into our customers’ supply chains, all while maintaining the highest standards of quality.

Our capabilities

- CNC laser-cutting

- CNC milling – horizontal and vertical 3 and 4-axis milling for close tolerance machining on exotic metals, phenolics and plastics

- CNC punching

- CNC waterjet

- Chemical treatment process including gold and clear chromate conversion coatings and advanced pre-treatment

- Complex assembly from aerospace body frames to interior supports, and sealing and bonding

- Finishing capabilities for wide variety of glosses and textured finishes

- Hardware installation – including rivets, studs and standoffs

- Stretch forming/bending

Current Products

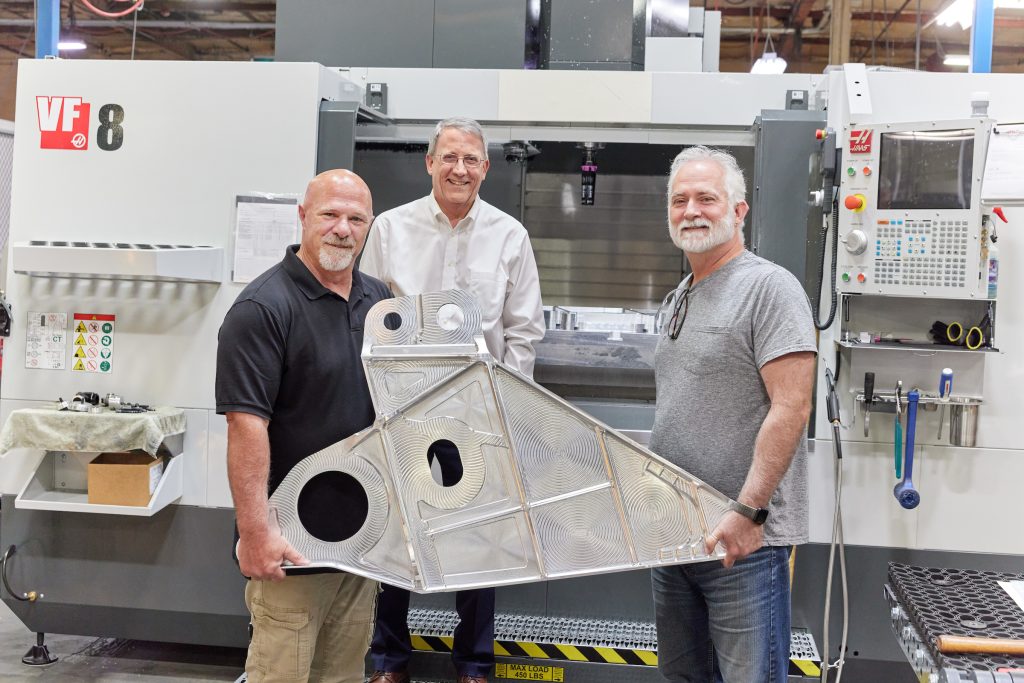

We manufacture and assemble aerospace parts for a wide array of commercial aircraft.

- Cockpit dashboard frame

- Metal/vinyl emergency doors

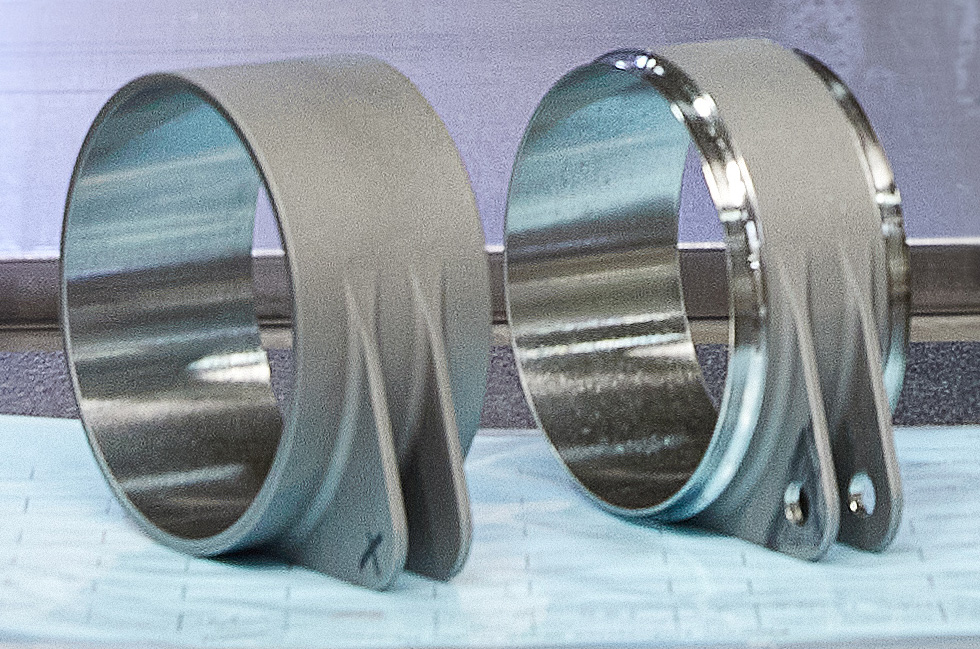

- Intricate fasteners, joints and hinges

Certifications

We are proud to maintain an extensive list of certifications and accreditations in the aerospace manufacturing industry, including:

Pioneer Industries has provided superior products to the Boeing company for over 50 years. Their ability to be responsive to our ever changing needs, especially requests to expedite even if overtime is required on a weekend, has been invaluable to all of the Boeing Commercial Airplane programs they support. We know we can always depend on them to come through for us. Their customer support and engineering team’s timely communication and collaboration have been invaluable to our success to build quality aircraft on time.

– Vicki Capperauld, BCA Structures Supply Chain Operations PA

Boeing

Contact us with questions:

Phone: 206-762-7737

Fax: 206-762-1982

Email: AerospaceParts@p-h-s.com

Making a Difference

As a nonprofit social enterprise, Pioneer Human Services provides treatment, housing, job skills and employment to individuals released from prison and jail and those in recovery from substance use disorders.

Pioneer Industries is proud to provide on-the-job training in aerospace manufacturing, while generating revenue to help fund our mission.

We believe in providing a chance for change and have built our award-winning manufacturing division with the leadership and assistance of formerly incarcerated employees. In 2024, 63% of our enterprise workforce had a conviction history and/or was in recovery from a substance use disorder.